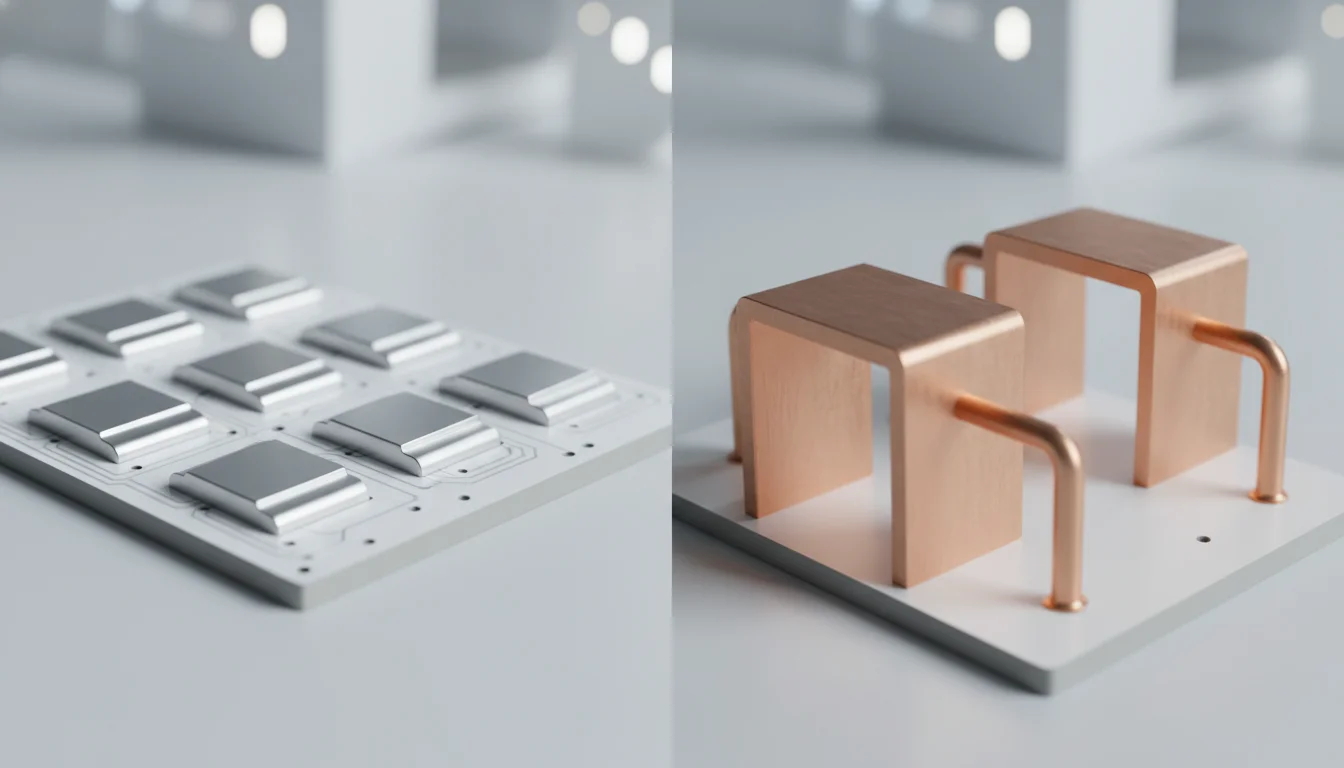

SMD vs. Through-Hole Terminal Cost Analysis: A Manufacturing Efficiency Matrix

Direct Answer: Switching from Through-Hole Technology (THT) to Surface Mount Device (SMD) terminals reduces total manufacturing costs by 30% to 50% for high-volume production. This cost saving is driven by the elimination of secondary wave soldering or manual welding steps, significantly faster pick-and-place automation, and a drastic reduction in defect rates (PPM) associated with manual handling.

Total Cost of Ownership (TCO) Deep Dive

When evaluating PCB connection solutions, many engineers focus solely on the unit purchase price. However, true cost optimization comes from the overall efficiency of the manufacturing process. Industry leaders like HC-SP emphasize that the Total Cost of Ownership (TCO)—including assembly time, yield loss, and equipment depreciation—must be calculated.

To help engineers quantify these differences, we recommend using our Price Calculator to estimate the specific cost impact for your production volume.

Manufacturing Efficiency Matrix: SMD vs. THT

The following table compares Welding/PCB Terminals (THT) against modern SMD solutions across key manufacturing metrics:

| Evaluation Metric | SMD Terminal (HC-SP Solution) | THT Terminal (Traditional) | Cost Impact |

|---|---|---|---|

| Assembly Speed | Very High (Thousands per hour, fully automated) | Slow (Manual insertion or odd-form placement) | SMD reduces labor costs by up to 80% |

| Process Steps | Single Reflow (Simultaneous with other parts) | Requires extra Wave or Manual Soldering | SMD eliminates secondary heat cycles |

| PCB Real Estate | No drilling required; allows double-sided mounting | Requires drilled holes; consumes routing space | SMD increases density, reducing PCB size/cost |

| Quality Consistency | Controlled by stencil printing precision | Dependent on operator skill; prone to cold joints | Significant reduction in Rework Rate (PPM) |

Why High-Current Applications are Shifting to SMD

Conventional wisdom once held that high-current connections required through-hole structures for mechanical strength. However, with advancements in SMD Busbar and SMT Nut technology, manufacturers like HC-SP have demonstrated that surface mount solutions can withstand high torque and high current (compliant with IEC 60068-2-58 standards).

The Hidden Benefits of Automation

- Simplified Inventory Management: SMD components are typically supplied in Tape & Reel packaging, facilitating smart warehousing.

- Nozzle Compatibility: HC-SP’s Precision Stamping parts are designed with flat pick-up surfaces to ensure compatibility with standard pick-and-place nozzles.

- Reduced Carbon Footprint: Elimination of wave soldering ovens reduces energy consumption and flux usage.

Selection & Implementation Guide

When transitioning from THT to SMD, following a proper Selection Guide is critical. For instance, in scenarios requiring extreme mechanical torque resistance, engineers can select SMD nuts with auxiliary positioning pegs, combining SMT efficiency with enhanced shear resistance.

HC-SP recommends considering the following standards during the design phase:

- IPC-A-610: Acceptability of Electronic Assemblies (Solder joint standards).

- IPC-7351: Generic Requirements for Surface Mount Design and Land Pattern Standards.

If you are weighing connection options for a new project or wish to test production line compatibility, please do not hesitate to Contact Us / Request a Sample. Our engineers can provide a detailed ROI analysis tailored to your specific needs.