WeChat ID

WeChat ID

Official Account

Official Account

WeChat ID

WeChat ID

Official Account

Official Account

Utilizing unique Solid-Liquid Cast-Rolling Technology to achieve atomic-level metallurgical bonding. This material reduces overall costs by over 40% and weight by over 50% compared to pure copper, serving as an ideal conductor for new energy and electrical equipment.

Manufactured using advanced Solid-Liquid Cast-Rolling Technology, this Copper-Aluminum Composite offers physical properties superior to traditional cladding or welding processes.

Simultaneous introduction of solid copper strip during aluminum phase transition ensures atomic penetration and eliminates delamination.

Eutectic layer precisely controlled at 300-500nm to balance bonding strength and conductivity.

Rounded edges for better fit with insulation materials, suitable for high-end busbar processing.

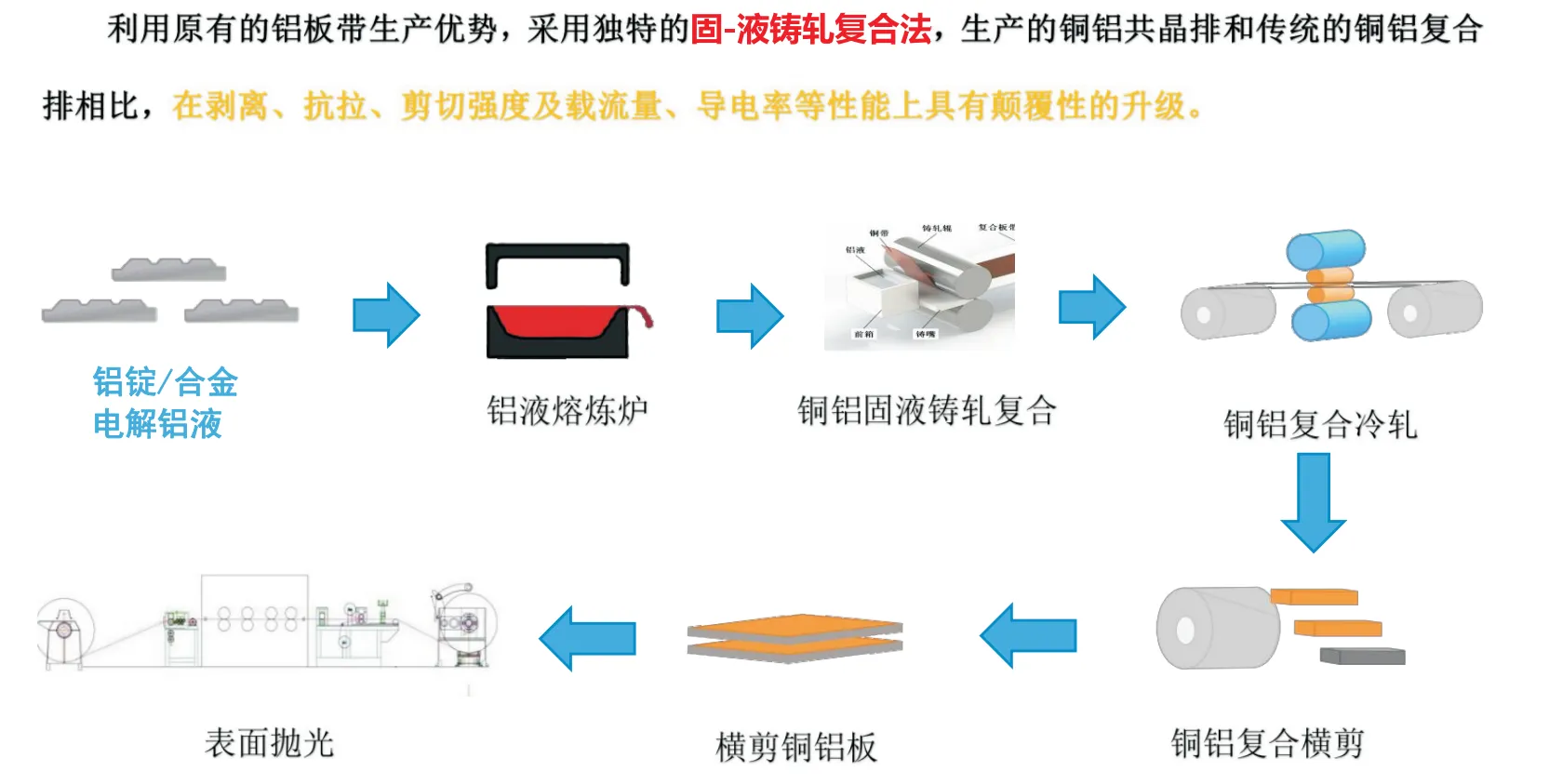

Process Principle: Solid-Liquid Cast Rolling Flow

Compared to traditional CCA (mechanical cladding/welding) and pure copper busbars, Solid-Liquid Cast-Rolling Cu-Al Eutectic Busbar offers significant advantages in bonding strength, processability, and cost-efficiency.

| Dimension | Pure Copper (T2/T3) | Traditional CCA (Clad/Weld) | Solid-Liquid Cast-Rolling Eutectic Busbar |

|---|---|---|---|

| Bonding Method | - | Mechanical/Weak Metallurgical | Atomic Metallurgical (Eutectic) |

| Peel Strength | - | Low (Prone to delamination) | > 148 N/mm (Very High) |

| Processability (Bending) | Excellent | Poor (Cracks/Peeling) | Excellent (90° No Cracks) |

| Conductivity (IACS) | ~100% | 65% - 85% | Customizable by Cu ratio |

| Density | 8.9 | ~3.5 - 4.5 | 3.94 (Lightweight) |

| Overall Cost | High | Medium | Low (40%+ savings vs Cu) |

* Note: Data based on typical values; specific performance depends on customization.

The following data is based on third-party authoritative testing, reflecting the excellent mechanical and electrical performance of the Cu-Al Eutectic Busbar.

| Test Item | Performance Data | Notes |

|---|---|---|

| Interface Peel Strength | > 148 N/mm | Far exceeds GB std, no cracking in processing |

| Shear Strength | > 63.6 N/mm | Stable and reliable structure |

| Tensile Strength | > 136 N/mm² | Excellent mechanical strength |

| Bending Performance | 90° No Cracks | Suitable for complex busbar bending |

| DC Resistivity | ≤ 0.02350 Ω·mm²/m | Better than national standard |

Single/Double-sided Cu customization. Thickness 1.5-12mm, Width up to 800mm.

| Spec (mm) | Current (50K Rise) | Weight vs Copper |

|---|---|---|

| 40 x 4 | ~468 A | 44% |

| 50 x 5 | ~635 A | 44% |

| 60 x 6 | ~903 A | 44% |

| 100 x 10 | ~1800 A | 44% |

We provide sample testing and selection support for this composite material.

Contact Us →