The Hidden Profit Killer in BMS Assembly: Manual Soldering

In the production of Battery Management Systems (BMS) and energy storage PCBA, many manufacturers still rely on manual labor to install high-current connectors, busbars, or fastening nuts. This traditional process faces three major challenges:

- High Labor Costs: Wages for skilled solderers are rising, and training takes time.

- Poor Consistency: Manual soldering is prone to cold joints, bridging, or misalignment, leading to high rework rates.

- Slow Takt Time: Manual operations cannot match the high speed of SMT lines, creating a bottleneck for the entire factory.

The Technical Shift: From "Post-Soldering" to "Full SMT Automation"

Integrating high-current components and mechanical fasteners into the SMT (Surface Mount Technology) process is key to cutting costs. By using specialized components capable of withstanding reflow soldering temperatures, factories can completely eliminate manual post-soldering stations.

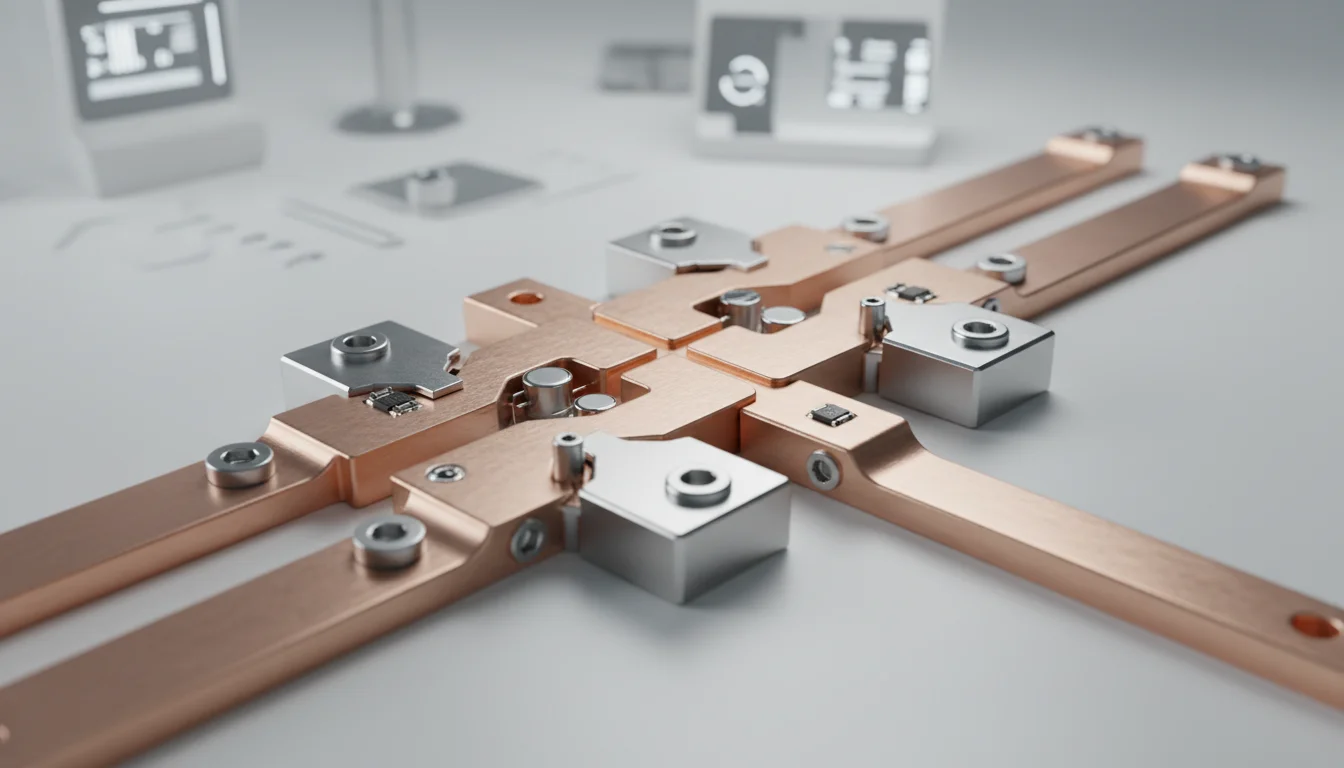

1. Replacing Copper Wires with SMD Busbars

Traditionally, handling currents above 50A required soldering copper wires or plates by hand. HC-SP's 贴片汇流条 (SMD Busbar) can be picked and placed just like capacitors or resistors. This not only improves current carrying capacity but also achieves zero manual intervention through tape-and-reel packaging.

2. SMT Nuts: No More Manual Screwing or Press-Fit

Mounting points on PCBs often require manual press-fitting or soldering of nuts. HC-SP's 贴片螺母 (SMT Nut) offers exceptionally high soldering strength (shear and torque forces meeting IPC standards) and can be soldered directly in the reflow oven, eliminating expensive press-fit equipment and labor costs.

Cost Analysis: How to Achieve 20% Savings?

Based on case studies from our clients, here is how the cost structure changes after adopting fully automated components:

- Direct Labor Cost: Reduced by approximately 60% (elimination of post-soldering and assembly stations).

- Quality Cost: Due to high machine positioning accuracy, defect rates dropped from 3000 PPM to under 50 PPM.

- Overall Efficiency: Production line UPH (Units Per Hour) increased by 35%.

You can use our online 价格计算器 (Price Calculator) to estimate the specific procurement and manufacturing cost differences when switching to SMT components.

The HC-SP Solution Advantage

HC-SP specializes in the SMT adaptation of high-current and mechanical components. Our product designs are optimized to ensure no deformation under lead-free reflow temperatures and feature excellent solder wicking performance.

- High Reliability: Precision stamping ensures coplanarity, preventing open joints.

- Customization: Tailored dimensions to fit your specific PCB layout.

Optimize Your Production Line Today

In this competitive market, manufacturing efficiency is the lifeline. If you are looking for cost-reduction solutions for BMS assembly, please 联系我们/索取样品 (Contact/Sample) immediately. Our engineers are ready to provide a free DFM (Design for Manufacturability) assessment.