Overcoming PCB High-Current Thermal Bottlenecks: Why SMD Busbars Are the Best Choice for Power Engineers

For hardware engineers, as designs for PV inverters, energy storage BMS, and high-power modules trend towards miniaturization, a major challenge arises: how to carry currents of 50A or even 100A within limited PCB space while controlling temperature rise.

Limitations of Traditional Solutions

Historically, to handle high currents, engineers relied on expensive or complex methods:

- Increasing Copper Weight: Using 3oz or 4oz heavy-copper PCBs. This drastically increases PCB manufacturing costs and limits fine-line etching capabilities.

- Manual Soldering or Screwing: Manually soldering thick wires or screwing copper bars onto the PCB. This process cannot be automated, leading to low production efficiency and poor consistency in mass production.

The SMD Busbar: A Revolutionary Solution

The SMD Busbar solutions provided by Shenzhen Hongchuan New Energy Materials are designed specifically to address these pain points.

1. Superior Current Capacity and Thermal Performance

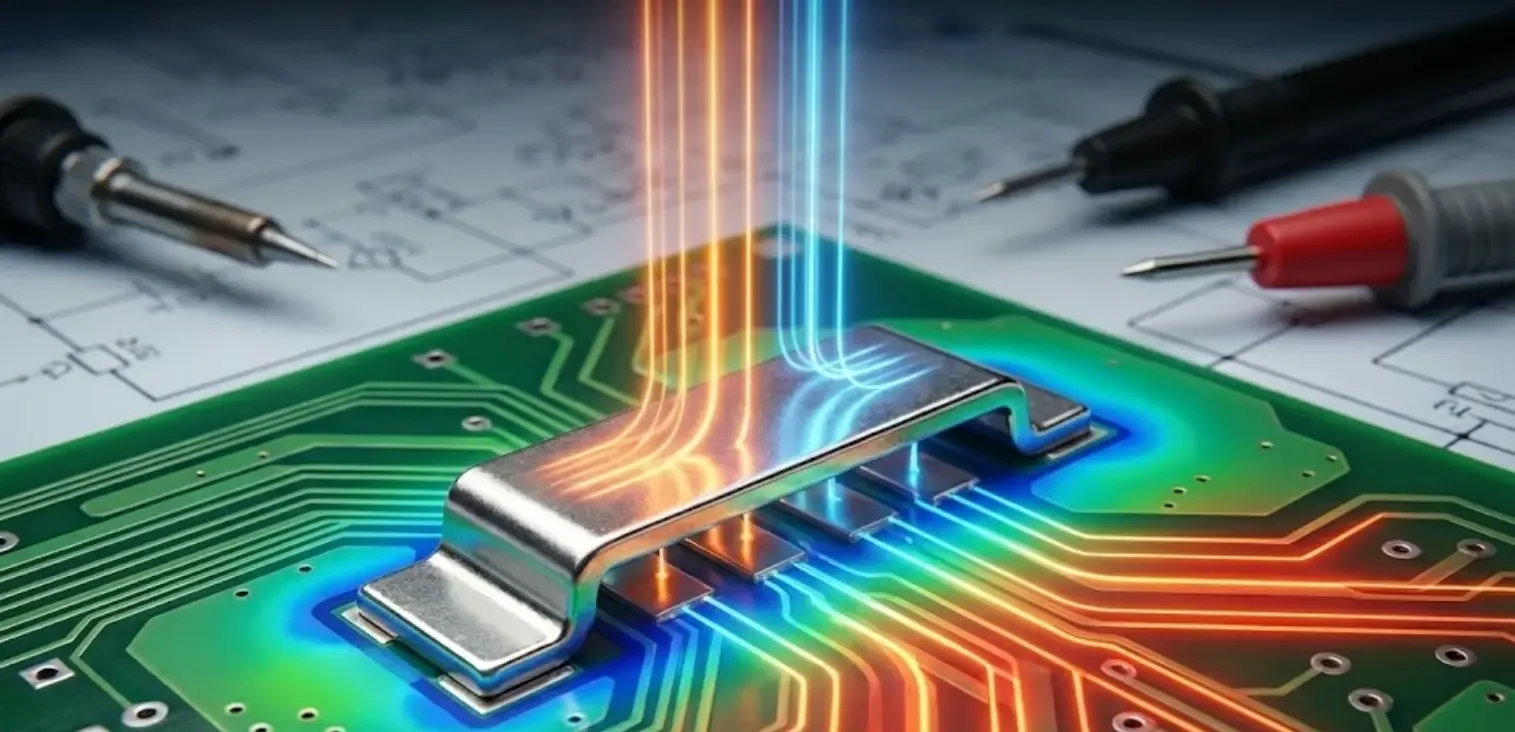

Our SMD busbars are stamped from high-purity copper with tin plating. Compared to flat PCB traces, the 3D design of the busbar offers a much larger cross-sectional area, significantly reducing DC Resistance (DCR). Test data shows that integrating SMD busbars can reduce temperature rise in high-current loops by 20% to 40%.

2. Fully Compatible with SMT Automated Processes

This is a key advantage for procurement teams focused on cost efficiency. Unlike traditional odd-form components, our products come in Tape & Reel packaging, making them fully compatible with standard pick-and-place machines. This means:

- No need for extra manual soldering stations.

- Reflow soldering ensures higher solder joint reliability.

- Significantly reduced assembly Cycle Time.

3. Saving Valuable PCB Real Estate

SMD busbars often feature a "jumper" design, allowing current to bridge over other traces on the PCB surface like an overpass. This offers immense flexibility in power layout, making it possible to achieve higher power density on smaller PCBs.

Applications

Currently, Hongchuan's SMD busbars are widely used in:

- Electric Vehicle (EV) Power Modules

- Photovoltaic (PV) Inverters

- High-Power Server PSUs

- Battery Management Systems (BMS)

Conclusion:

If you are struggling with PCB high-current thermal issues or looking to cut costs on heavy-copper boards, contact the engineering team at Shenzhen Hongchuan New Energy Materials. We offer both standard off-the-shelf parts and custom tooling services to help make your hardware design more competitive.