2025: The "Life or Death" Race for Solid-State Batteries

As the global new energy industry sets its sights on 2025, this year is widely regarded as the pivotal moment for solid-state battery technology to move from the laboratory to commercial pilot production. From Toyota and VW to CATL, leading companies have announced their mass production timelines. However, for battery structural engineers, the new physical architecture brought by solid-state electrolytes means that traditional battery pack designs must be completely overhauled. In this context of high-frequency iteration, traditional hardware mold development has become a stumbling block for R&D.

Hongchuan Precision (HC-SP) deeply understands industry pain points. Targeting the R&D needs of 2025, we have fully upgraded our custom stamping services, launching a "No-Mold" rapid prototyping solution to help companies race against time during the prototype validation phase.

"No-Mold" Technology: Breaking the Shackles of Traditional Stamping

In traditional battery pack R&D, design changes often involve expensive progressive die modifications, with cycles lasting several weeks. HC-SP's "No-Mold" solution does not completely abandon tools but employs a hybrid process combining laser cutting, wire EDM, and simple bending dies (soft tooling). This process is particularly suitable for prototyping and small-batch pilot production (1-500 pieces).

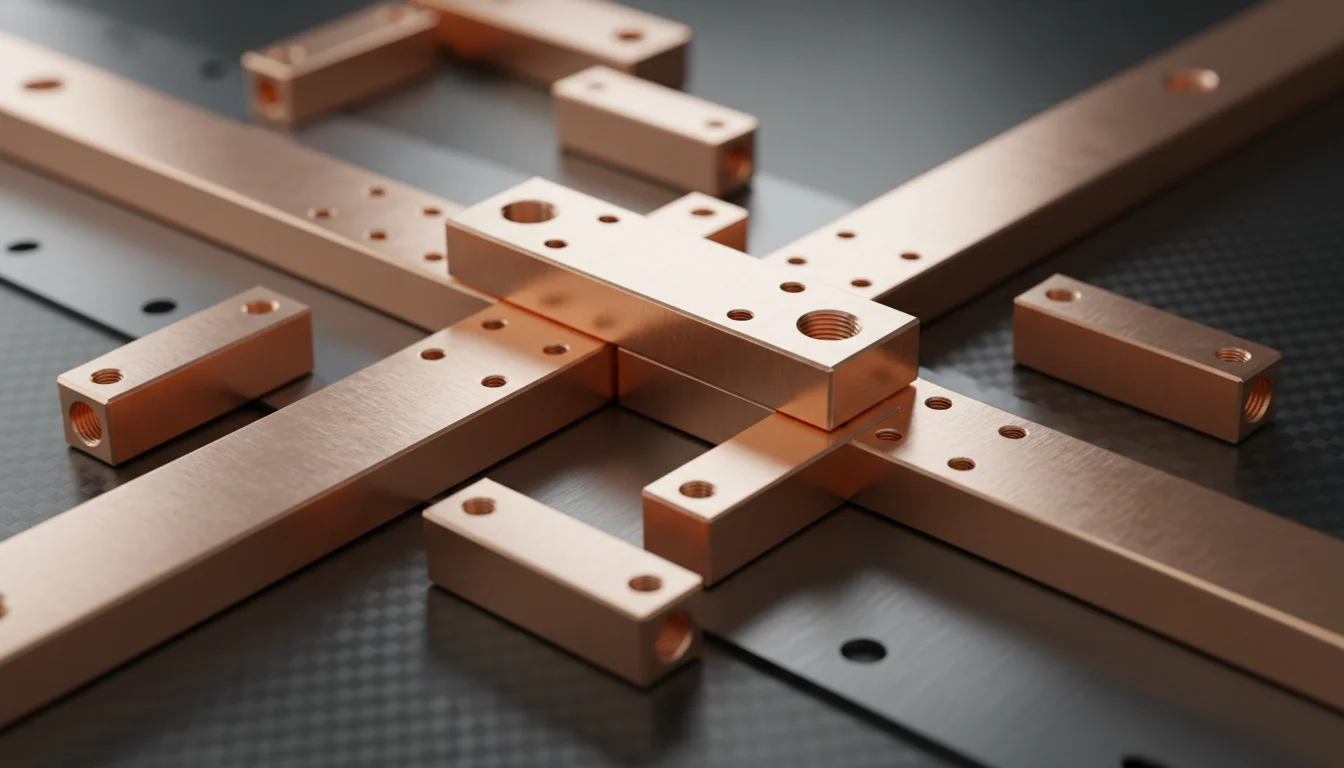

1. Rapid Validation of Busbars

The extreme pursuit of energy density in solid-state batteries requires connectors to be lighter, thinner, and capable of carrying higher currents. Traditional busbar designs often require adjustments in thickness and heat dissipation hole positions during the validation phase. Through HC-SP's laser forming technology, we can deliver copper busbar samples of different configurations within 24 hours, allowing engineers to immediately conduct temperature rise tests without waiting for expensive hard molds.

2. Flexible Iteration of Complex Terminals

The internal space of new battery modules is extremely compact, placing high demands on the bending angles and contact surface shapes of welding terminals. Utilizing high-precision CNC bending equipment, HC-SP can achieve multi-angle complex forming, ensuring a perfect match between PCB terminals and battery tabs. This flexibility allows customers to lock in the optimal design scheme during the B-sample stage.

Innovative Solutions for PCB-Level Connections

In addition to power transmission paths, the fixing of the BMS (Battery Management System) also faces challenges. To adapt to automated production lines, more and more solid-state battery packs are adopting SMT processes. The SMT nut provided by HC-SP not only supports tape-and-reel packaging for automatic placement but its unique design also prevents solder floating, passing strict reflow soldering tests. During the prototype stage, we can provide various specifications of SMT nuts for customers to conduct peel force tests, ensuring connection reliability.

Seamless Transition from Prototyping to Mass Production

Many customers worry that the precision of "No-Mold" samples may not match future mass-produced parts. HC-SP implements strict standardization management in our manufacturing process. Our engineering team considers Design for Manufacturability (DFM) when designing prototypes, ensuring that product performance remains consistent when transitioning from laser samples to continuous die production.

You can visit our product center to view more success stories regarding new energy connectors. If you are selecting components for a new solid-state battery project, we recommend consulting our selection guide to understand the performance differences of various materials (such as C1100 copper vs. C7025 copper-nickel-silicon alloy).

Start Your Rapid Prototype Project Today

Time is money, especially in the technology-explosive new energy track. To facilitate engineers in quickly assessing costs, the HC-SP official website has launched a price calculator. You only need to input basic dimensions and materials to get a preliminary budget.

Ready to accelerate your 2025 R&D plan? Please contact us immediately to request free samples or conduct in-depth technical consultations. HC-SP looks forward to being your solid backer on the road to solid-state battery commercialization.