WeChat ID

WeChat ID

Official Account

Official Account

WeChat ID

WeChat ID

Official Account

Official Account

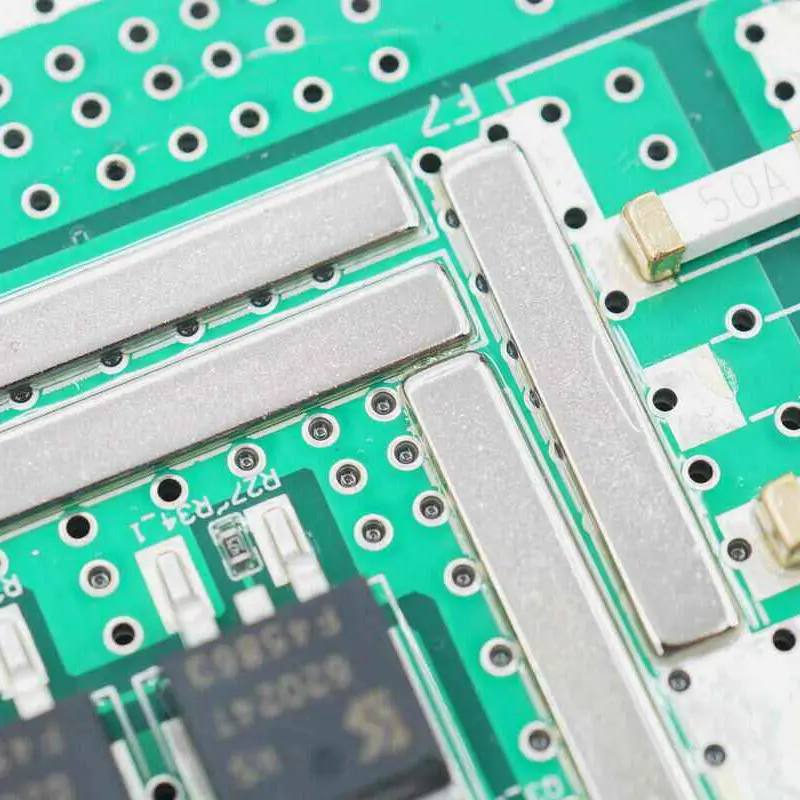

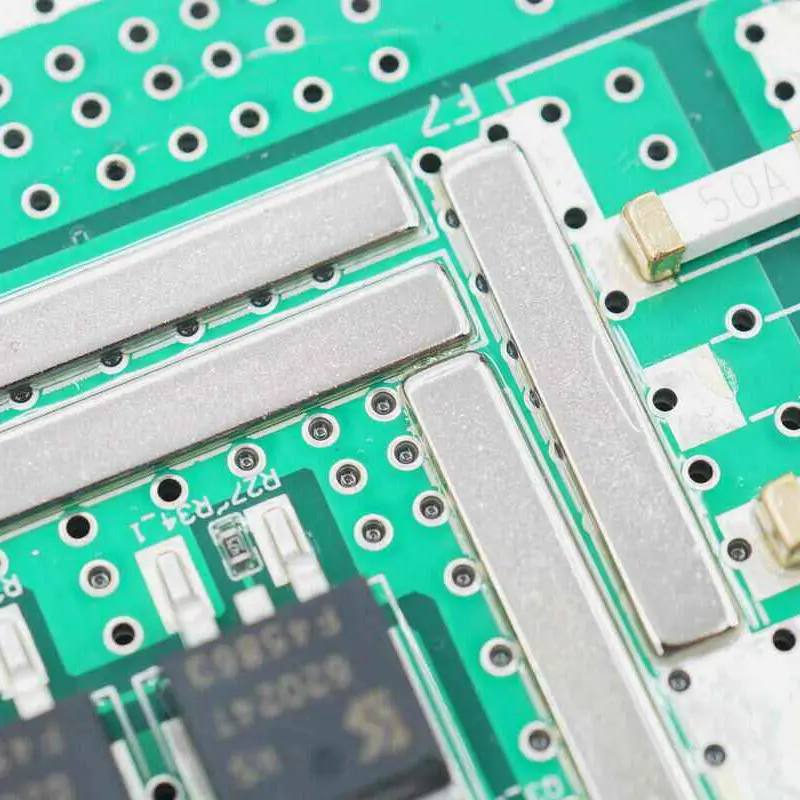

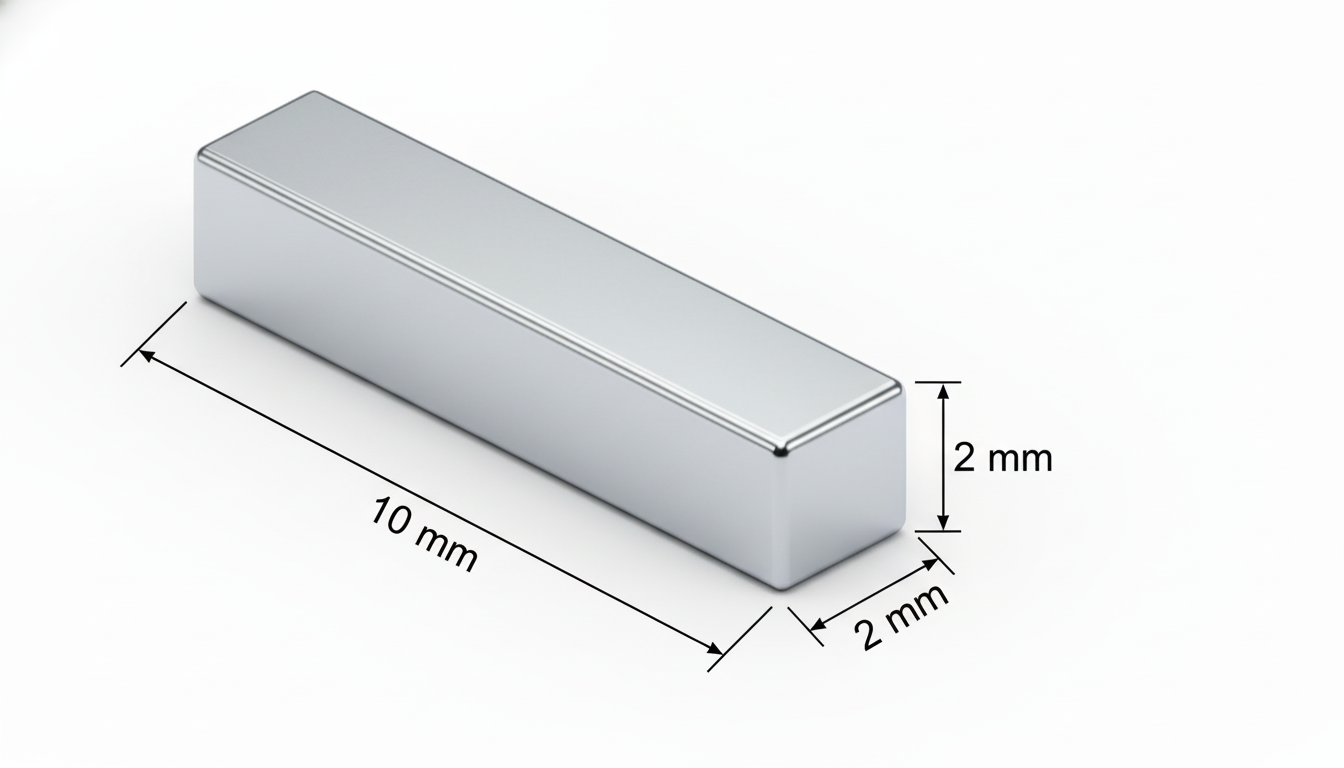

HCSP series busbars are crafted from diverse metal materials including T2 copper, H62 brass, manganese steel, aluminum, and copper-aluminum composites through precision stamping. The products feature excellent electrical and thermal conductivity, capable of handling current ranges from 10A to over 800A. Surface treatments include tin, nickel, silver, or gold plating, forming a dense protective layer to effectively resist oxidation and corrosion. Widely used in new energy vehicle battery systems, energy storage interconnections, photovoltaic inverter distribution, industrial automation control cabinets, and other high-reliability applications, providing long-term stable solutions for power transmission.

Detailed product parameters and performance

| Material | T2 Copper, H62 Brass, Cu-Al Composite, Manganese Steel, Aluminum |

| Thickness Range | 0.3mm - 3.0mm |

| Current Capacity | 10A - 800A+ |

| Surface Treatment | Tin, Nickel, Silver, Gold Plating |

| Temperature Rise | <30K @ Rated Current |

| Contact Resistance | <0.1mΩ |

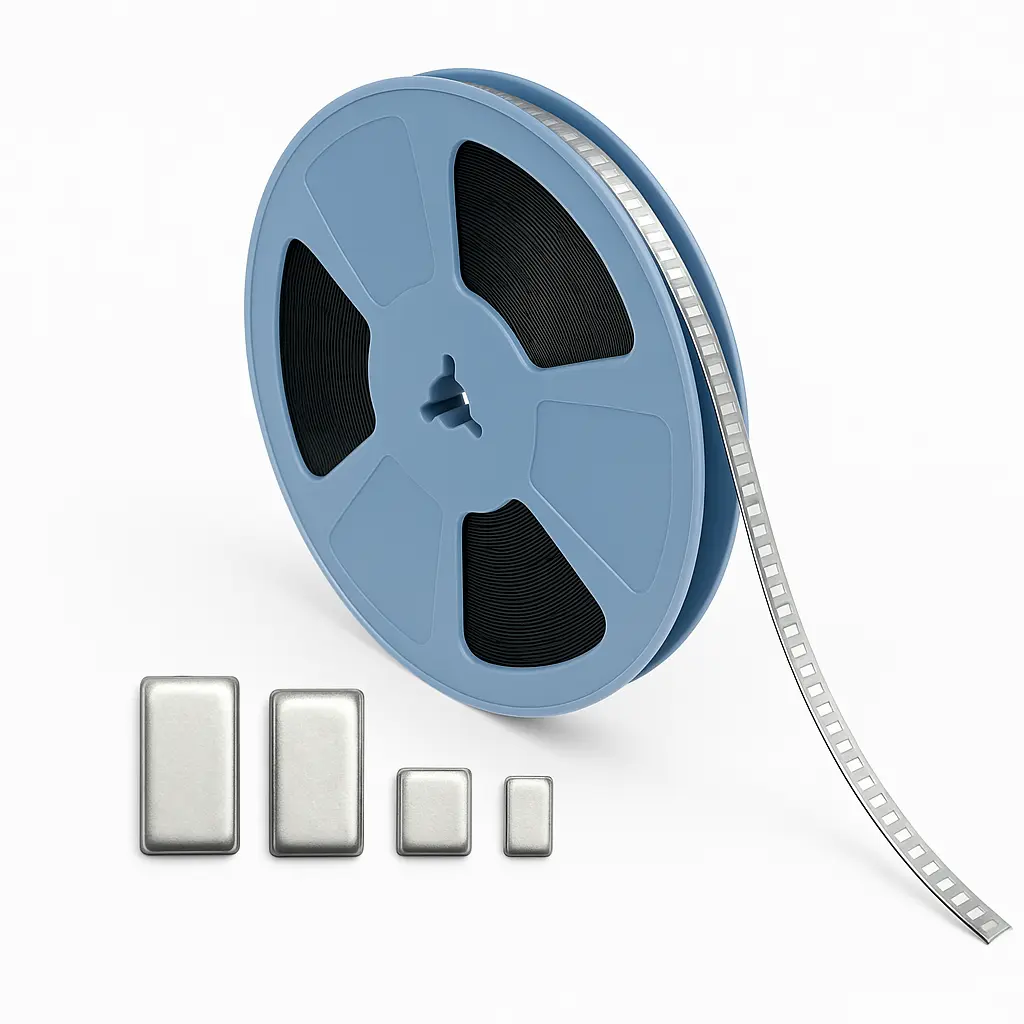

| Packaging | Bulk, Tape Reel (SMT Compatible) |

| Certifications | RoHS, REACH, ISO9001 |

Selected high-quality busbar products with rapid customization

Widely used in new energy and industrial sectors

Battery pack busbars, BMS terminals, charging systems

Module connection, distribution terminals, monitoring

DC busbars, AC terminals, IGBT connection

VFD, PLC cabinets, servo drivers

High power modules, power distribution

SMPS, DC/DC converters, UPS systems

Professional busbar manufacturer provides complete busbar custom solutions from design to mass production. With 6000+ standard busbar mold library, 3-day rapid tooling for custom busbars, full-spec SMT tape packaging support for high current busbars in new energy vehicles and energy storage systems.