GB38031-2025 is Here: Why the "2-Hour" Rule Changes Everything

With the release of the GB 38031-2025 standard (Safety Requirements for Power Batteries in Electric Vehicles), the industry faces a paradigm shift. The old "5-minute alarm" rule is obsolete. The new standard mandates that after a single cell thermal runaway, the battery pack must not catch fire or explode for at least 2 hours (or indefinite non-propagation).

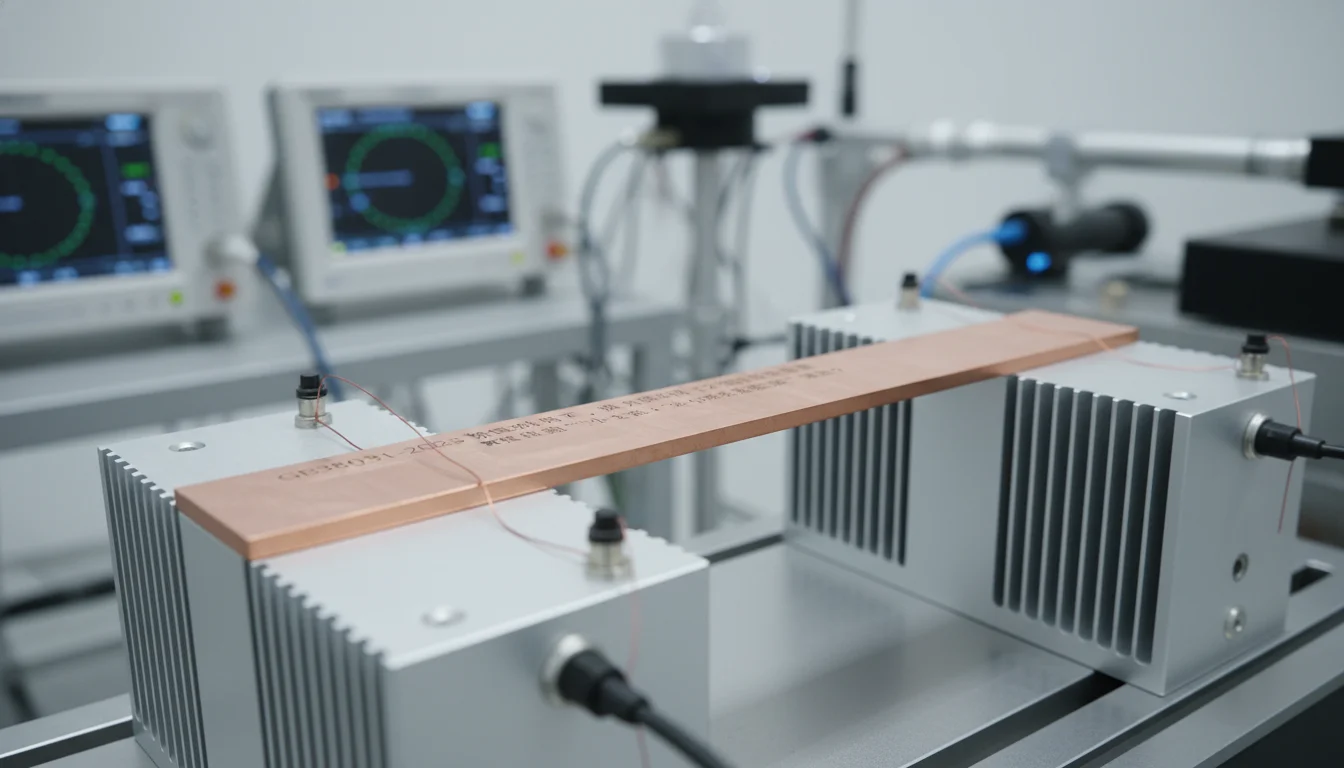

For OEMs, this usually means skyrocketing costs due to expensive aerogels or complex liquid cooling systems. However, there is a smarter, lower-cost way to manage heat propagation: optimizing your conductive structural components. Specifically, using high-performance SMD busbars and T2 copper connectors.

The Science: T2 Copper as a Thermal Heat Spreader

Thermal runaway mitigation is about heat flux management. You can either block the heat (insulation) or move it away (dissipation). Blocking heat with aerogels is expensive. Moving heat with copper is cost-effective.

T2 Copper has a thermal conductivity of ~395 W/(m·K), nearly double that of aluminum. By connecting cells with optimized copper busbars, you create a "thermal highway." When one cell fails and overheats, the copper busbar rapidly extracts heat from that cell and spreads it to the cooler parts of the module or the structural frame, lowering the peak temperature of the failing cell and preventing adjacent cells from reaching their trigger point.

HC-SP's Strategy for Thermal Compliance

At HC-SP, we engineer our interconnects to serve dual purposes: electrical conduction and thermal safety.

1. Surface Area Optimization

Through custom precision stamping, we design busbars with integrated fins or wave structures in non-contact areas. This acts as a passive heatsink, dissipating heat into the air gap or potting material much faster than flat bars.

2. Robust Welding Terminals

During thermal runaway, connection points face temperatures exceeding 800°C. Standard aluminum connections may melt, causing arcs. HC-SP's welding terminals are made from high-purity copper with high-temperature plating, ensuring the structural integrity of the heat path remains intact during the event.

3. Expansion-Ready Designs

Swelling is a major issue during battery failure. Rigid bars can break or damage terminals. We incorporate stress-relief features (similar to those used in our SMD nuts packaging technology) to allow the busbar to flex without disconnecting, maintaining both electrical and thermal continuity.

The Cost Benefit

Upgrading from standard busbars to HC-SP's thermally optimized T2 copper busbars costs a fraction compared to adding full-pack aerogel insulation. You can estimate the potential savings for your specific batch size using our online price calculator.

Success Story

A leading energy storage client struggled to pass the new 2-hour delay requirement. Their initial design used aluminum bars and heavy insulation but failed at 45 minutes. HC-SP recommended switching to a custom-designed T2 copper busbar with a 30% larger thermal cross-section. The result? The heat spread effectively, preventing propagation for over 140 minutes, passing the test while reducing the overall pack weight and cost.

Ready to Pass the Test?

Compliance with GB38031-2025 doesn't require breaking the bank. It requires smart engineering. Explore our product center to see our range of high-performance interconnects.

Don't risk failure. Contact us today for a consultation and request samples of our thermal-management-ready copper busbars.