Thermal Crisis in 800V Platforms and 5C Supercharging

As the electric vehicle (EV) industry rapidly evolves towards 800V high-voltage platforms and 5C-6C supercharging technologies, integrated electric drive systems (3-in-1, All-in-One) are facing unprecedented power density tests. With peak currents instantly exceeding 600A, traditional connection methods struggle to meet thermal dissipation requirements. Engineers urgently need to find advanced board-level connection solutions in our Product Center to prevent system throttling or failure caused by localized PCB overheating.

Solder Terminals: High Efficiency in Compact Spaces

In compact electric drive controllers, space is at a premium. New generation solder terminals are replacing traditional bolted connections. By utilizing high-conductivity copper alloys combined with unique heat dissipation structural designs, HC-SP's SMD solder terminals can withstand continuous high-current surges. Furthermore, they support automated reflow soldering, significantly reducing contact resistance and minimizing Joule heat generation at the source.

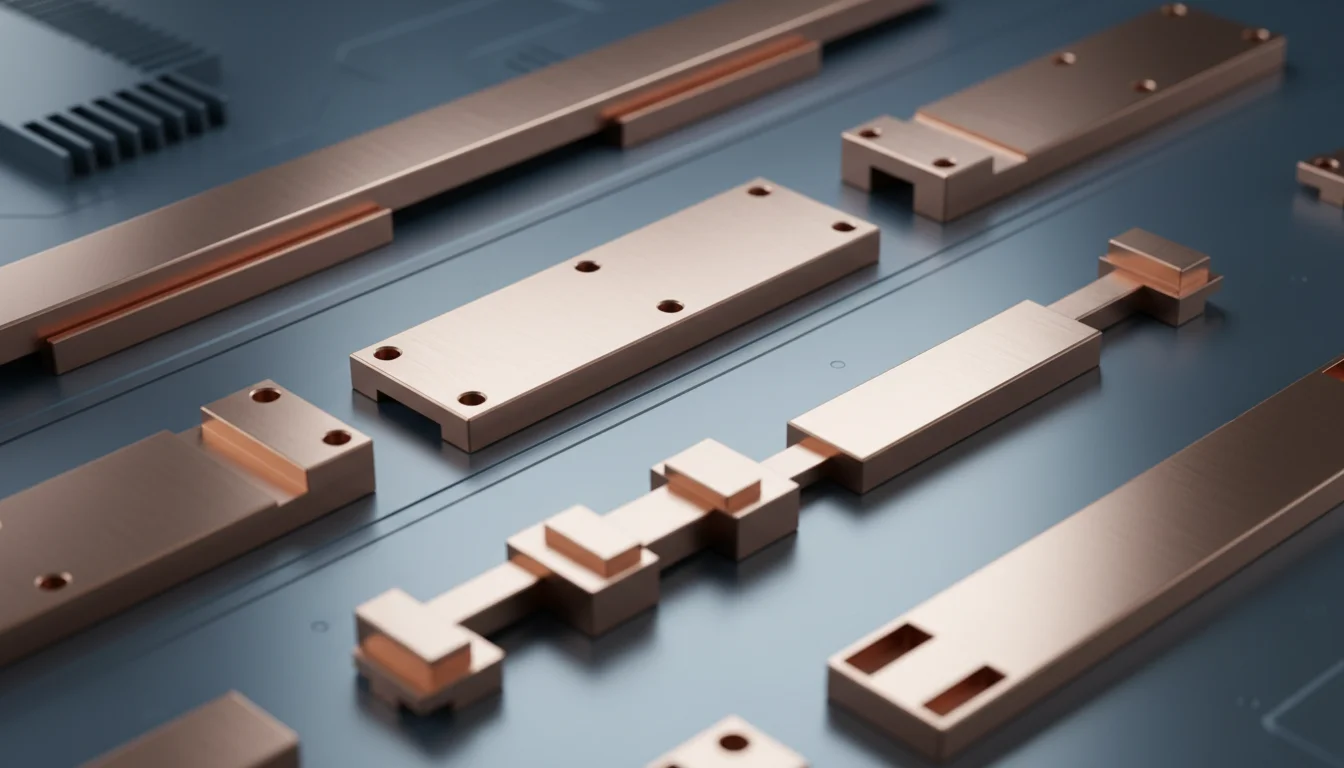

SMD Busbars: Key to Solving Localized PCB Overheating

Simply thickening PCB copper foil is no longer sufficient to handle the transient high heat of 5C charging. In this scenario, the SMD busbar becomes a critical component for thermal management. Acting as a "highway" on the PCB, it not only carries currents of up to several hundred amperes but also serves as an efficient thermal path, rapidly conducting heat away from power devices like SiC MOSFETs. Compared to traditional copper bars, SMD busbars offer lower parasitic inductance, making them ideal for high-frequency switching environments.

Precision Stamping Ensures Connection Reliability

Under conditions of high-frequency vibration and extreme temperature fluctuations, the mechanical strength of connectors is vital. HC-SP's precision stamping technology ensures the dimensional consistency of every terminal and busbar, with flatness strictly controlled within 0.05mm to guarantee a perfect fit with the PCB. Additionally, for scenarios requiring mechanical fixation, we offer complementary SMT nut solutions to further enhance the system's vibration resistance.

Conclusion: Customization Powers Future Drives

Facing rapidly changing supercharging technologies, standard parts often fail to meet specific design requirements. If you are developing next-generation 800V electric drive systems, please contact us. HC-SP's engineering team is ready to provide comprehensive support, from material selection to structural optimization, helping you overcome thermal challenges.