In recent years, fires involving Electric Vehicle (EV) battery packs and Energy Storage Systems (ESS) have frequently made headlines. While cell chemistry is often blamed, industry investigations reveal a surprising culprit hiding in the assembly details: loose electrical connections. On production lines chasing aggressive Takt Times, traditional manual or semi-automatic nut tightening processes are becoming the "Achilles' heel" of quality control.

The Invisible Killer: Thermal Runaway from Torque Deviations

A battery pack contains hundreds of electrical connection points. According to industry data, increased contact resistance due to loose joints is a primary external cause of local overheating and thermal runaway. When high current flows through a terminal face that isn't perfectly mated, the instantaneous Joule heating can melt insulation and ignite the battery.

Traditional module assembly relies heavily on manual torque application. This introduces uncontrollable variables:

- Human Error & Fatigue: Even with calibrated torque wrenches, variations in operator angle and downward pressure can cause the actual clamp force to deviate by ±20% or more.

- Torque Decay: Soft materials (like copper busbars or insulation pads) creep over time, causing initial torque to drop significantly hours after assembly.

- Vibration Failure: Micro-vibrations during transport can gradually loosen mechanical connections that lack a metallurgical bond.

The Technical Shift: Replacing Mechanical Locks with SMT

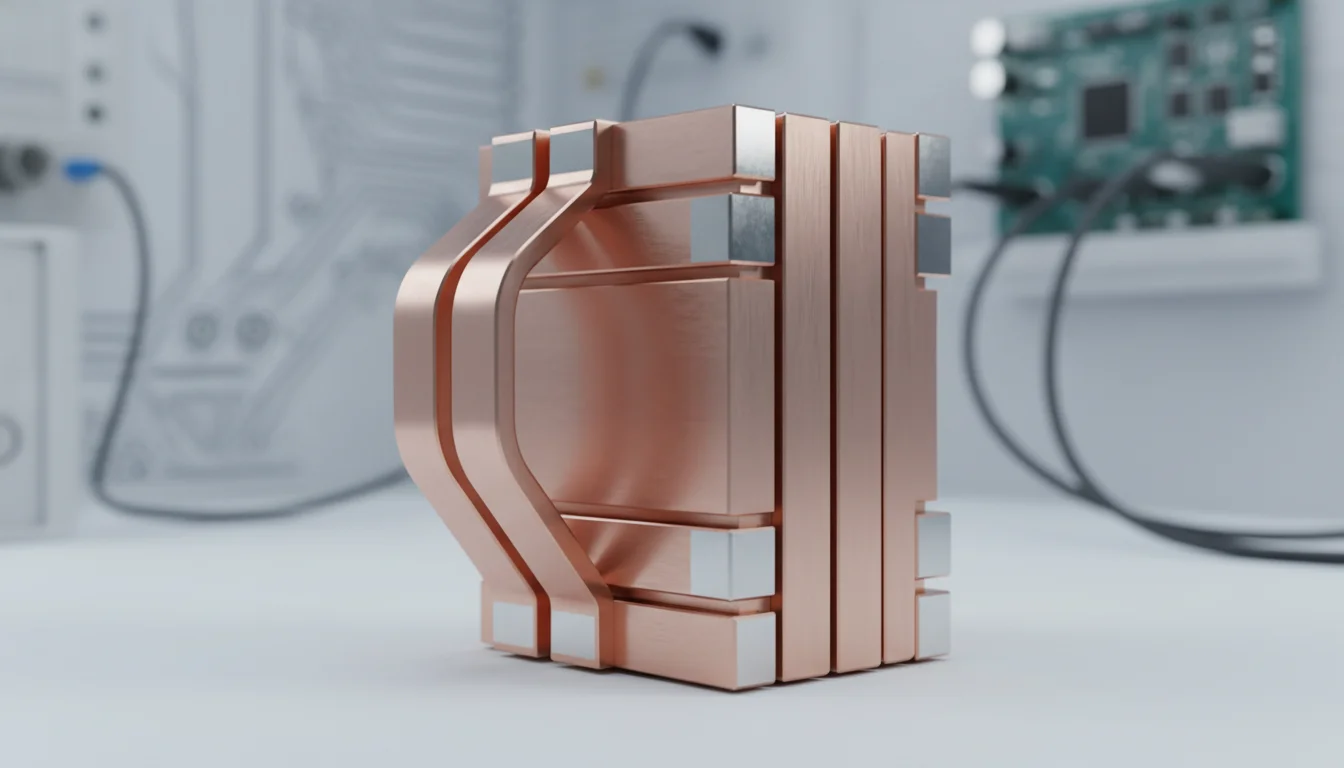

To eliminate "human factors" at the source, leading battery manufacturers are integrating electrical connections into the SMT (Surface Mount Technology) automated process. By using HC-SP precision SMD nuts, the nut becomes an electronic component, soldered directly onto the PCB or copper-clad laminate via reflow soldering.

Why are SMT Nuts Safer?

| Feature | Manual/Press-Fit Nuts | HC-SP SMD Nut Solution |

|---|---|---|

| Connection Principle | Mechanical Friction | Metallurgical Bond (Solder) |

| Consistency | Human dependent, high variance | 100% Machine Vision, Zero Deviation |

| Vibration Resistance | Prone to loosening | High shear strength, vibration proof |

| Efficiency | Low, requires secondary ops | High, processed with PCB |

The HC-SP Solution: Designed for High Current & Reliability

Hongchuan Precision (HC-SP) understands the battery industry's pain points. We go beyond standard parts, offering specialized SMD fasteners created through custom precision stamping. Our core advantages include:

- Superior Coplanarity: Controlled within 0.08mm to ensure perfect contact with the solder pad during reflow, preventing "open" joints.

- Optimized Tin Plating: Ensures rapid wetting of solder paste at high temperatures, creating a bond with exceptional torque shear resistance.

- Tape & Reel Packaging: Perfectly compatible with Siemens, Panasonic, and other pick-and-place machines for fully automated production.

In practical applications, our SMT nuts are often paired with SMD busbars to build efficient current transmission paths from the PCB to the battery module. This fully automated connection method not only reduces labor costs but, more importantly, provides traceable, standardized safety assurance for every battery pack.

Conclusion: Safety Cannot Be Compromised

As battery energy densities rise, even microscopic assembly errors can lead to catastrophe. Shifting from "relying on people" to "relying on process" is essential for manufacturing upgrades. Choosing HC-SP's SMD nuts means choosing a safer future for connectivity.

Want to upgrade your battery assembly line to SMT automation? Visit our Product Center to view specifications, or contact us directly to request free samples and technical guidance.