The Invisible Killer of EV R&D: Long Customization Lead Times

When developing high-performance BMS boards, high-power inverters, or charging stations, hardware engineers often face a dilemma. Traditional PCB traces can no longer meet the thermal and current-carrying requirements as power density surges. At this point, copper SMD Busbars or power terminals become essential. However, traditional suppliers often require drawings, mold opening, and trial production, a process that typically takes 4-6 weeks. In the fast-paced new energy market, a 30-day delay can mean missing the market window entirely.

HC-SP: Breaking the Mold of 'Mandatory Tooling'

HC-SP has specialized in precision hardware for years, understanding that 'Speed' and 'Precision' are critical during the R&D phase. We have established a comprehensive Standard Component Library, covering everything from miniature copper strips to high-current power terminals.

- No-Mold Customization: Leveraging advanced automated processing, HC-SP can fine-tune standard components based on your PCB layout, eliminating expensive mold fees and long waiting times.

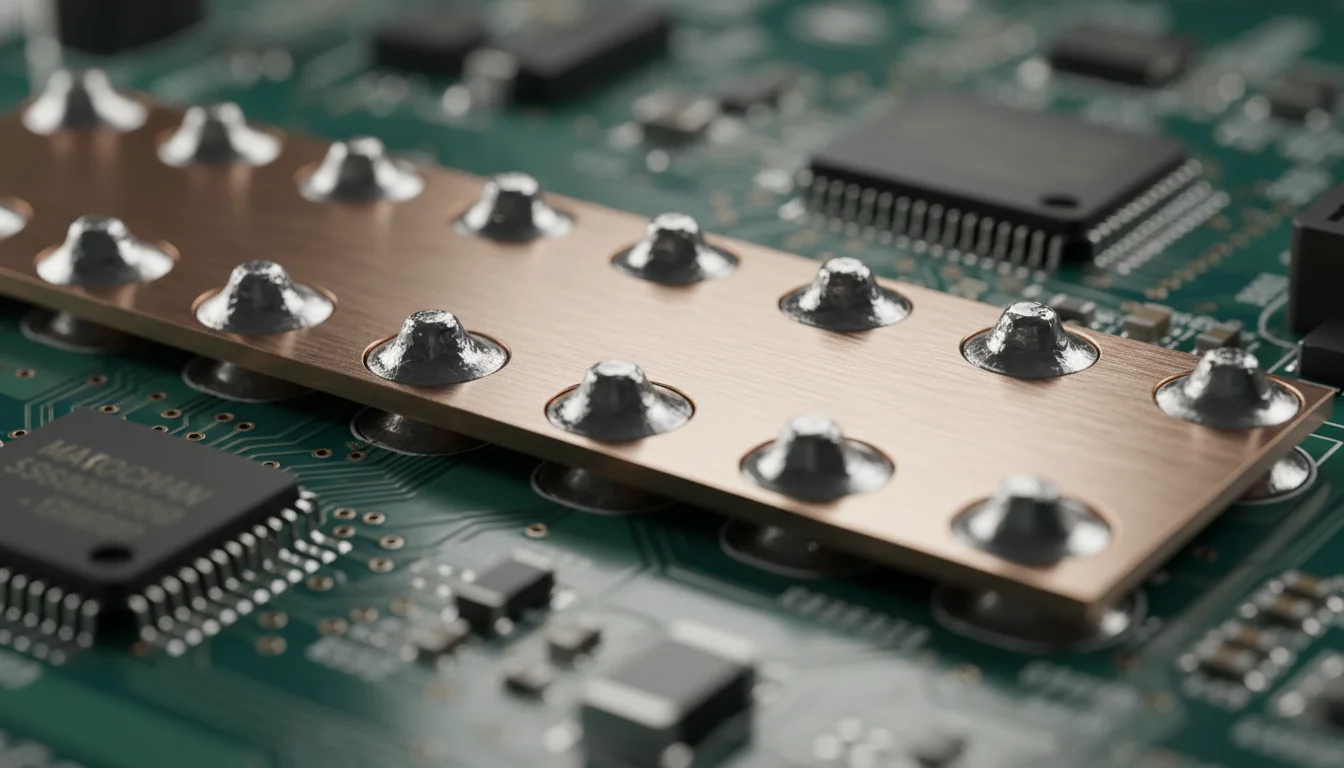

- Superior Material & Finish: We utilize high-conductivity T2 Copper or Brass with tin-plated surfaces, ensuring extremely low contact resistance and excellent SMT soldering reliability.

- Thermal Management Optimization: HC-SP SMD busbars are designed specifically for high-current applications, effectively reducing localized PCB temperature rise and enhancing stability under high loads.

From BMS to ESS: Full-Scenario Connection Solutions

Whether it's battery pack connections in EVs, power inputs for industrial controllers, or busbars in energy storage systems (ESS), HC-SP provides perfectly matched hardware components. Our SMD Nuts and Standoffs support direct assembly via automated pick-and-place machines, significantly boosting production efficiency and reducing labor costs.

Source Factory Empowering Global Engineers

As an ISO9001 certified original manufacturer, HC-SP provides not only high-quality products but also professional technical support. We offer:

- Rapid Prototyping: Sample delivery as fast as 3-7 days to support prototype testing.

- Selection Guidance: Matching the optimal model for your project based on current values, temperature rise limits, and footprint sizes.

- Cost Optimization: Standardized production ensures competitive pricing, paving the way for large-scale mass production.

Contact HC-SP today to request a free sample kit and accelerate your R&D cycle.