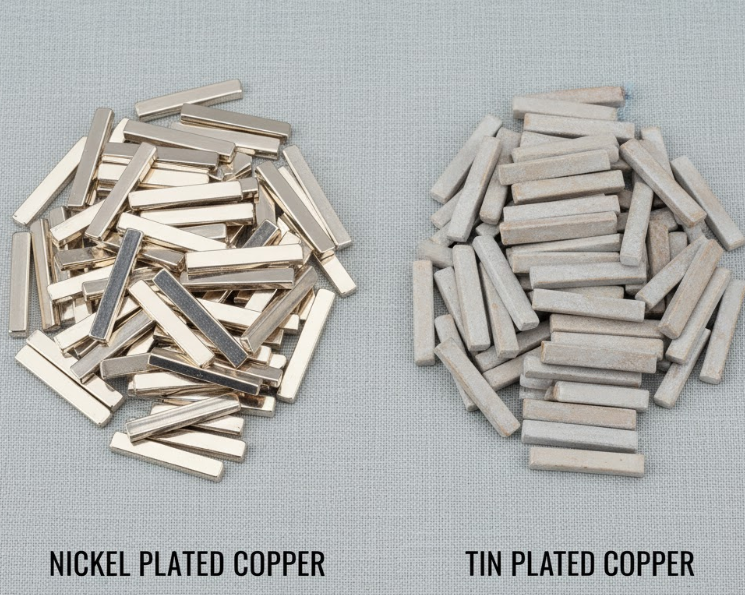

In high-current PCB systems, the choice between nickel-plated and tin-plated busbars directly impacts reliability and performance. Although both provide surface protection, their performance diverges under high-power and high-temperature conditions. This article explores the key differences and explains why nickel-plated busbars are now the preferred option for EVs, energy storage, and 5G equipment.

Advantages of Nickel-Plated Busbars

-

Superior Corrosion Resistance: Nickel coatings form a dense and stable surface that prevents oxidation even in humid or saline environments.

-

High Hardness & Durability: Ideal for frequent plug-in/out or high-pressure assembly use.

-

Thermal Stability: Nickel layers resist deformation and prevent tin whisker formation.

-

Reliable Soldering: Excellent wetting performance and strong adhesion during SMT production.

Where Tin Plating Still Works

Tin-plated busbars remain suitable for low-power, cost-sensitive applications like household appliances and low-voltage systems.

Summary

Nickel plating ensures long-term stability, high-temperature endurance, and corrosion protection — making it the optimal surface finish for high-current PCB designs in the modern energy industry.